Contact Us

|

Home

Contact Us

|

Home

Contact Us

|

Home

Contact Us

|

Home

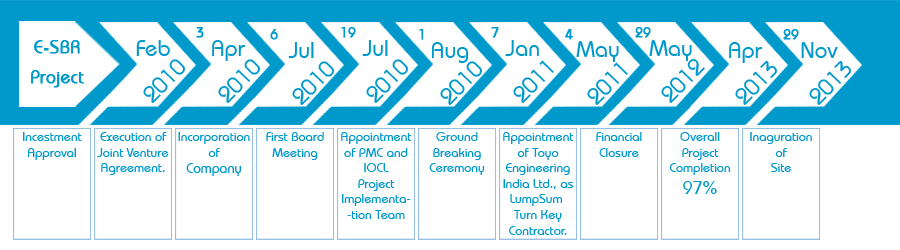

Project

The flag ship project, spread over 57acres, comprises of a process unit, a state of the art rubber finishing line, a robot controlled packaging and loading equipment, offsite storage facilities, a DM water plant, an advanced effluent treatment plant including a reverse osmosis (RO) plant with zero-liquid effluent discharge, cooling water system and instrumental plant air system, informs the CEO.

"ISRPL (formerly known as ISRL) is backed by the R&D expertise of TSRC, who have many patents and innovations specific to synthetic rubber and thermoplastic elastomers. TSRC's R&D centre located at Kaohsiung, Taiwan, is having state-of-art facilitates to cater to the product application and development needs of the industry. Further, there are many experienced experts and an accomplished technical service team to serve the tyre customers and ascertain the quality of E-SBR. The emulsion pilot plant, which facilitates development of new e-SBR grades, can comply with growing demands of the customers, Elangovan Dakshinamurthy, COO told Rubber Asia.

ISRPL's (formerly known as ISRL) project provides value addition to the Butadiene stream of IOCL's Panipat Naphtha Cracker Plant (PNCP). Further, it also enhances synergies by sharing critical utilities like steam, power and raw water necessary for the operation. The IOCL's plant will also synergistically benefit from ISRPL's (formerly known as ISRL)plant by way of reduced hydrogen consumption and corresponding reduction in greenhouse gas (GHG) emissions.